Khoom

Tag nrho granulation muaj nuj nqi thiab siab ntau lawm efficiency

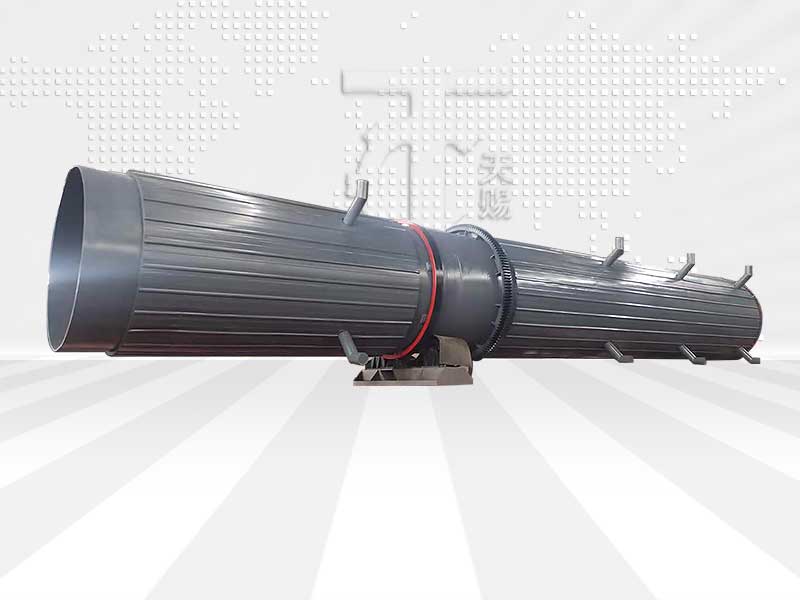

Txias Rotary Drum Cooler Tshuab

Khoom Taw Qhia

Rotary nruas txias tshuab yog siv rau txias chiv nrog tej yam kub thiab particle loj hauv kev lag luam chiv.

Cov yam ntxwv ua haujlwm

Txoj cai ua haujlwm

Rotary Drum Cooler txais kev hloov pauv cua sov rau cov ntaub ntawv txias.Nws yog nruab nrog welded steel kauv scraping tis nyob rau hauv pem hauv ntej ntawm lub raj, lifting board nyob rau hauv lub kawg ntawm lub teb lub cev, thiab auxiliary piping system nyob rau hauv lub feed kawg ntawm lub tshuab txias.Txoj siv thiab rubey yog tsav los ntawm lub ntsiab lub cev muaj zog thiab los ntawm lub reducer, tus tsav ncej yog muab tso rau hauv cov lus tsa suab.

Technical parameters ntawm ib chim txias

| Qauv | Peev xwm (t / h) | Ceev (r / min) | Lub cev muaj zog | Lub zog (KW) | Qauv: Reducer | hnyav (t) |

| φ1.2 × 12 | 1.9-2.5 Nws | 4.5 | Y160L-6 | 11 | ZQ 50 | 22 |

| φ1.5 × 15 | 4-6 | 4.5 | Y200L1-6 | 18.5 Nws | qw 65 | 33 |

| φ2 × 20 | 7–8 | 3 | Y225M-6 | 30 | ZL 75 | 74 |

| φ2.2 × 22 | 10-11.5 Nws | 3 | Y225M-6 | 30 | ZL 75 | 82 |

| φ2.5 × 25 | 11-15 | 3.5 | Y280S-6 | 45 | ZL100 | 108 |

| φ2.8 × 28 | 14-17 | 3.5 | Y280M1-6 | 55 | ZL100 | 142 |

| φ3 × 30 | 16-20 | 3.5 | YS2-355M1-6 | 112 | ZL115 | 156 |

Thov ib daim Quote

Xaiv tus qauv thiab tso xaj

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau tus nqi pib

Cov neeg tsim khoom siv lub tswv yim los tiv tauj thiab qhia rau lo

Kev tshuaj xyuas cog

Cov kws tshaj lij qhia kev cob qhia, kev rov mus xyuas tsis tu ncua

Kos npe rau daim ntawv cog lus

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau txais qhov tsawg kawg nkaus pub dawb, thov sau cov ntaub ntawv hauv qab no los qhia peb (cov ntaub ntawv tsis pub lwm tus paub, tsis qhib rau pej xeem)

Project Case

Granular organic chiv ntau lawm project ntawm 30000 tons ib xyoo

- Muaj peev xwm:30000TP xyoo

- Input loj:≤0.5 hli

Kawm ntxiv Koom nrog peb

Standardized cemented carbide cov khoom lag luam muaj cov khoom muag loj, cov khoom lag luam customized tuaj yeem tsim tshiab thiab pwm tiav.

Tau txais cov lus hais

Tau txais cov lus hais +8613203835178

+8613203835178