Khoom

Tag nrho granulation muaj nuj nqi thiab siab ntau lawm efficiency

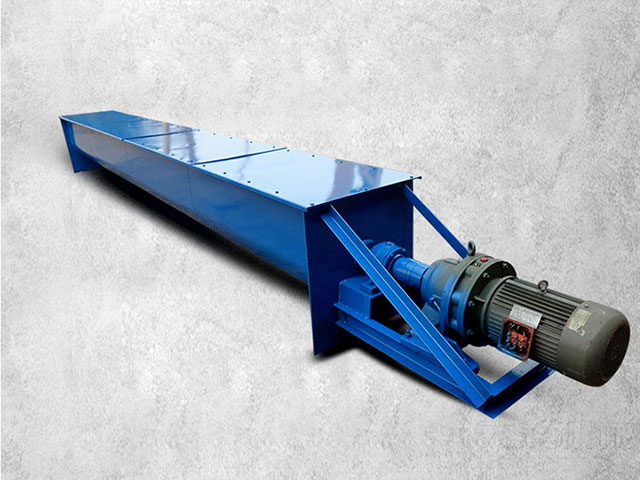

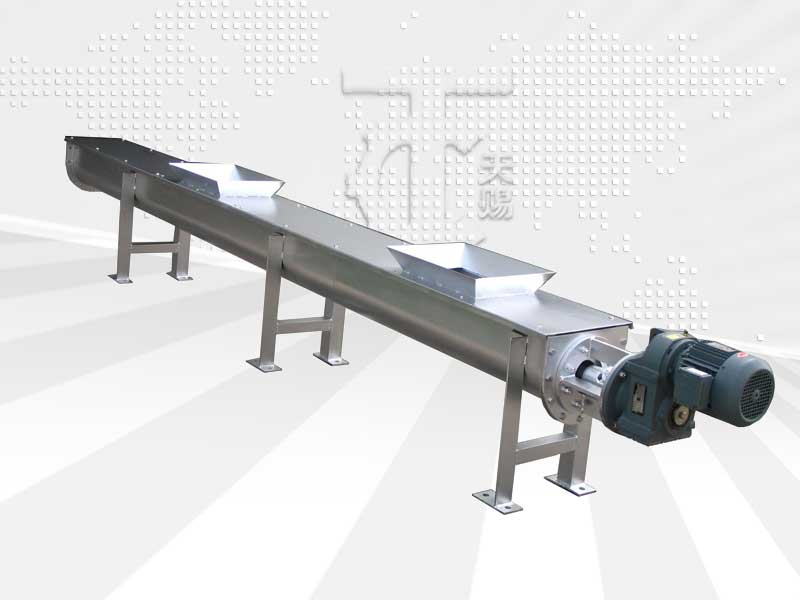

Ntsia hlau conveyor rau chiv / tshuaj / kev lag luam thiab metallurgy

Product Description

Cov ntsia hlau conveyor siv cov yeeb nkab steel conveying lub tog raj kheej, uas muaj kev nruj nruj, kev sib khi zoo, tsis muaj dej, thiab txhim kho qhov chaw ua haujlwm.

Cov khoom siv kis tau tus mob txais lub cev muaj zog ncaj qha txuas nrog cycloidal pinwheel reducer, uas muaj lub zog siab, tsis tshua muaj suab nrov, cov qauv compact thiab txhim khu kev qha.Lub tshuab tag nrho tuaj yeem ntsia tau kab rov tav lossis obliquely, nrog me me hneev taw, yooj yim installation thiab siv tau yooj yim.

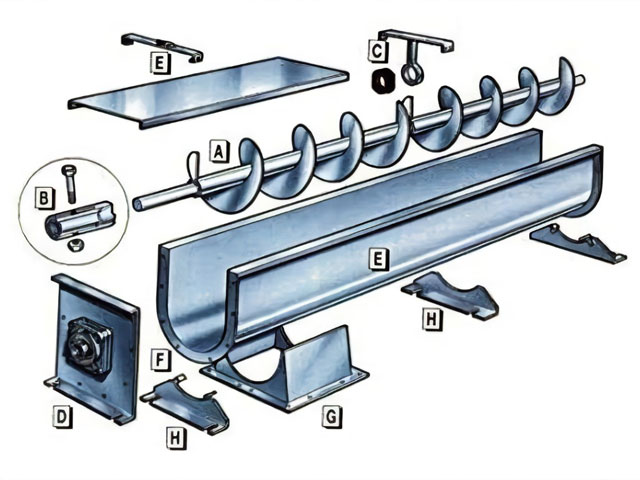

Lub tshuab tuaj yeem muab faib ua peb ntu

1. Cov ntsia hlau conveyor yog ib hom tsis yog qhov yooj yim.Nws yog tsim los ntawm cov cuab yeej siv lub cev muaj zog thiab lub raj casing, thiab cov ntsia hlau sib dhos yog txuas rau ib leeg, thiab muab tso rau hauv cov khoom tiav, uas yooj yim heev rau kev txav, disassemble thiab sib sau ua ke.

2. Cov ntsia hlau sib dhos thiab cov ncej kawg yog txuas nrog splines, uas yog yooj yim rau kev sib sau thiab disassemble, muaj peev xwm loj bearing, zoo nruab nrab, thiab muaj kev nyab xeeb thiab txhim khu kev qha.

3. Lub sealing kev ua tau zoo, lub plhaub yog ua los ntawm seamless steel yeeb nkab, thiab txhua qhov kawg yog txuas nrog flanges, tag nrho lub tshuab tsis muaj plua plav to, thiab tsis muaj cov ntaub ntawv pov tseg, thiaj li tsim kom muaj kev ua haujlwm zoo thiab ua tau raws li kev tiv thaiv ib puag ncig. kev xav tau.

4. Qhov loj me, kev kub ceev, lub suab sib txawv, kom ntseeg tau tias xa khoom sai thiab txawm tias xa khoom.

5. Lub chaw noj mov tuaj yeem ua rau lub kaum sab xis xav tau raws li qhov chaw ua haujlwm, thiab tuaj yeem txuas nrog flange, lub hnab sib txuas thiab universal flange, uas tuaj yeem xaiv los ntawm cov neeg siv khoom raws li lawv xav tau.

Technical Parameters

| Qauv | Kauv txoj kab uas hla (mm) | Rotary ceev (r / min) | Txheem ntim khoom xa tuaj (m3 / h) |

| SIB 160 | 160 | 112 | 9.7-3.2 Nws |

| 90 | 7.8-2.6 | ||

| 71 | 6.2-2.1 | ||

| 56** | 4.9-1.6 | ||

| LS 200 | 200 | 100 | 16.9-5.6 Nws |

| 80 | 13.5-4.5 Nws | ||

| 63 | 10.7-3.6 | ||

| 50** | 8.5-2.8 | ||

| LS 250 | 250 | 90 | 29.9-9.9 Nws |

| 71 | 23.5-7.8 Nws | ||

| 56** | 18.5-6.2 Nws | ||

| 45** | 14.9-5.0 Nws | ||

| SIB 315 | 315 | 80 | 52.9-17.6 Nws |

| 63 | 41.6-13.9 Nws | ||

| 50** | 33.1-11.0 Nws | ||

| 40** | 26.4-8.8 Nws | ||

| LS 400 | 400 | 71 | 85.3-28.2 Nws |

| 56 | 67.3-22.4 Nws | ||

| 45** | 54.1-18 | ||

| 36** | 43.2-14.4 Nws |

Thov ib daim Quote

Xaiv tus qauv thiab tso xaj

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau tus nqi pib

Cov neeg tsim khoom siv lub tswv yim los tiv tauj thiab qhia rau lo

Kev tshuaj xyuas cog

Cov kws tshaj lij qhia kev cob qhia, kev rov mus xyuas tsis tu ncua

Kos npe rau daim ntawv cog lus

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau txais qhov tsawg kawg nkaus pub dawb, thov sau cov ntaub ntawv hauv qab no los qhia peb (cov ntaub ntawv tsis pub lwm tus paub, tsis qhib rau pej xeem)

Project Case

Kawm ntxiv Koom nrog peb

Standardized cemented carbide cov khoom lag luam muaj cov khoom muag loj, cov khoom lag luam customized tuaj yeem tsim tshiab thiab pwm tiav.

Tau txais cov lus hais

Tau txais cov lus hais +8613203835178

+8613203835178