Khoom

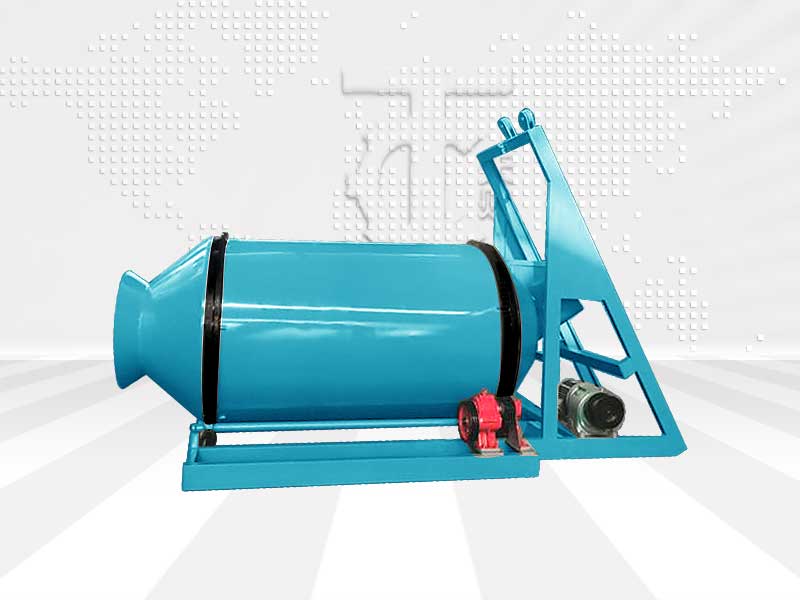

Tag nrho granulation muaj nuj nqi thiab siab ntau lawm efficiency

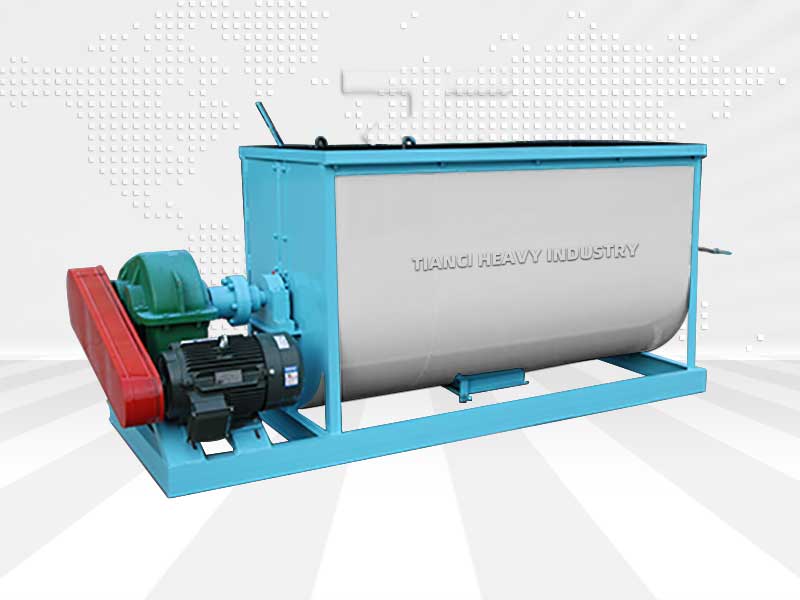

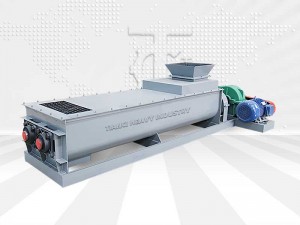

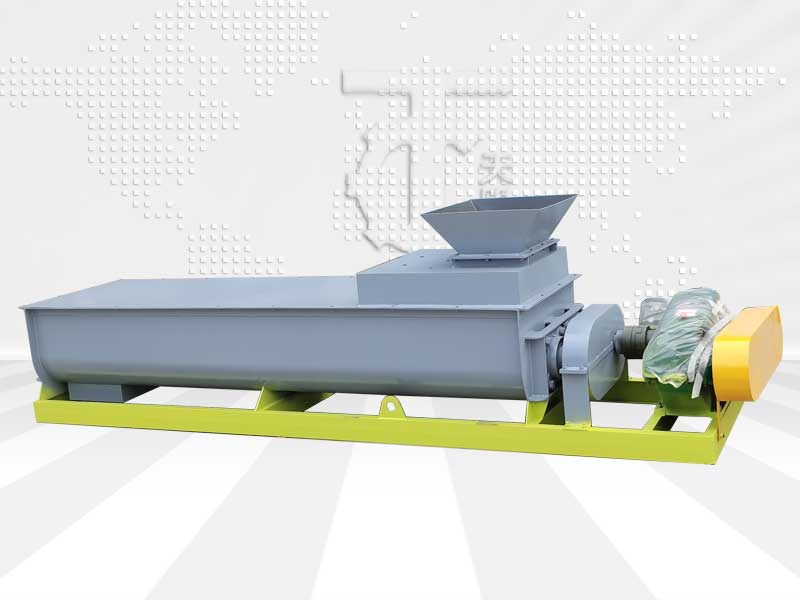

Ob Chav Shafts Kab rov tav tov khoom

Daim ntawv thov thiab nta

1.Kev saib xyuas cov khoom

Lub tshuab yog lub koom haum ua liaj ua teb kev tshawb fawb tshuab siv xyoo compound chiv ua khoom tsim, kev tsim khoom tsim hauv cov khoom siv thev naus laus zis tshiab, tau txais lub teb chaws cov tswv yim patent.Nws yog siv rau granulation rau txhua yam ntawm cov organic teeb meem tom qab fermentation, tawg los ntawm cov pa organic prilling ua ntej granulation yuav tsum tsis txhob qhuav thiab crushed raw cov ntaub ntawv.Nws tuaj yeem coj lub nra hnyav rau kev ua haujlwm tawm cylindrical lis, tuaj yeem txuag tau ntau lub zog

2. Cov yam ntxwv ntawm cov khoom siv

(1) Cov khoom granule yog cylindrical

(2) Cov ntsiab lus organic tuaj yeem siab txog 100%, ua cov organic granulate

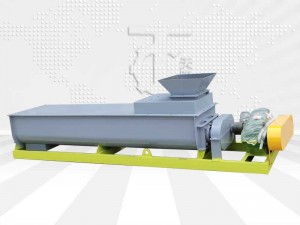

(3) Siv cov khoom siv organic nrog kev sib koom tes mosaic loj hlob nyob rau hauv ib qho kev quab yuam, tsis tas yuav ntxiv binder thaum granulating.

(4) Cov khoom granule yog loj, nws muaj peev xwm sieve ncaj qha tom qab granulation kom txo tau lub zog noj ntawm qhuav.

(5) Tom qab fermentation organics tsis tas yuav qhuav, noo noo ntawm raw cov ntaub ntawv yuav nyob rau hauv 20% -40%

(6) Forth, Mixing hniav vuam nyuaj steel cuab tam me ntsis, hnav-tiv taus kev ua tau zoo, kev pab lub neej ntev.

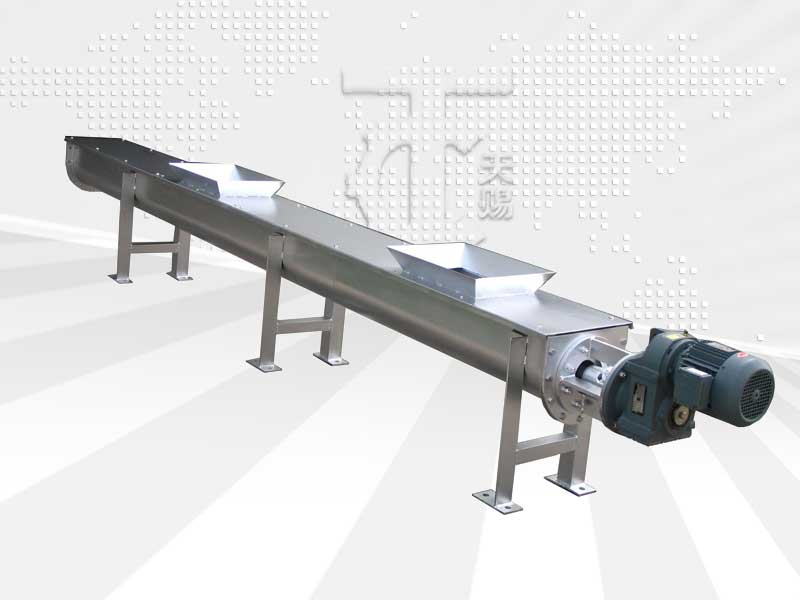

Txoj Cai Ua Haujlwm

Ua ntej, qhov kev faib tawm ntawm cov hmoov nyoos ntws mus rau hauv lub tank sib xyaw los ntawm kev qhib qhib thiab tom qab ntawd dej uas tau muab tso rau hauv qee qhov kub.

Qhov thib ob, siv ib qho ntev Ncej los ntawm kev sib xyaw vane los sib tov cov hmoov nyoos thiab tom qab ntawd tsim ib lub pob tawg uas muaj qee yam dej noo.

Thib peb, muab lub pob zeb nuclear tso rau hauv lub pob phaj thiab do.Tag nrho stirring faib mus rau hauv atomization cheeb tsam, stir tsam, tso tawm tsam.

Main Technical Parameters

| Model ZYQ-QZ | Ceev reducer JZQ | Hluav taws xob lub cev muaj zog | Spindle ceev (Y / mm) | Rotating txoj kab uas hla (mm) | Khoom Muaj Peev Xwm | Nyhav KG |

| 400 | 400-1V-2 | Y160M-4-11 | 52 | 400 | 20 | 2350 |

| 450 | 500-1V-2 | Y160L-4-15 | 52 | 450 | 25 | 26 20 |

| 500 | 500-1V-2 | Y180M-4-18.5 | 53 | 500 | 30 | 2980 ua |

| 550 | 650-1V-2 | Y180L-4-22 | 53 | 550 | 35 | 3 450 |

| 600 | 650-1V-2 | Y200L1-4-30 | 52 | 600 | 40 | 3 850 |

| 650 | 750-1V-2 | Y225S-4-37 | 52 | 650 | 45 | ib 4260 |

Thov ib daim Quote

Xaiv tus qauv thiab tso xaj

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau tus nqi pib

Cov neeg tsim khoom siv lub tswv yim los tiv tauj thiab qhia rau lo

Kev tshuaj xyuas cog

Cov kws tshaj lij qhia kev cob qhia, kev rov mus xyuas tsis tu ncua

Kos npe rau daim ntawv cog lus

Xaiv tus qauv thiab xa qhov kev xav yuav khoom

Tau txais qhov tsawg kawg nkaus pub dawb, thov sau cov ntaub ntawv hauv qab no los qhia peb (cov ntaub ntawv tsis pub lwm tus paub, tsis qhib rau pej xeem)

Project Case

Kawm ntxiv Koom nrog peb

Standardized cemented carbide cov khoom lag luam muaj cov khoom muag loj, cov khoom lag luam customized tuaj yeem tsim tshiab thiab pwm tiav.

Tau txais cov lus hais

Tau txais cov lus hais +8613203835178

+8613203835178